What is our initial willingness to purchase an briquette machine? We of course hope to increase the production through the equipment, thus creating higher economic benefits eventually. It is always an issue of concern for the manufacturers as for the production efforts of the briquetting machine. Good quality makes good production, and Zhongzhou Machinery has faith in manufacturing briquette machine all the way. Whether the equipment can operate well is affected by various factors. As for the aspect of research and development of the coal briquette machine, Zhongzhou has its own idea. And we also have our own scheme in improving the level of production of ore powder briquette machine.

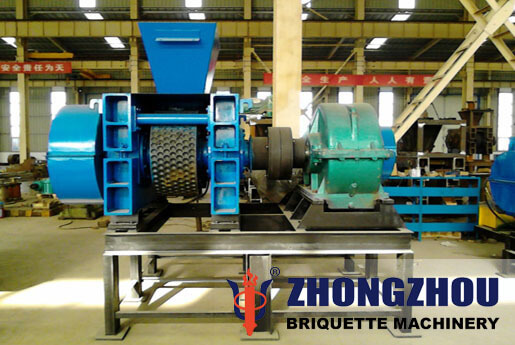

The ore powder briquette machine has a reliable quality and serves several purposes with a strong pressure. It suits for those small, medium and large enterprises that have a certain production scale of production line. After many years use and improvement in industry, compared with the other similar products, the ore powder briquette machine has the obvious advantages of high ball forming rate, low power consumption, compact structure and easy maintenance and debugging, etc.

To improve the production level of ore powder briquette machine effectively, we should take different measures according to the machine models:

1. By testing the various powers and making comparison with each other, we can determine the quality of ore powder briquette machines; the roller spacing and roll speed have a great influence on molding, so we can improve the production level of ore powder briquette machine through controlling the roller spacing and roll speed strictly.

When the spacing of the same ore powder briquette machine is too large, the briquettes will fall down before the ore powder briquette machine reaches the center position of briquette. This not only affects the briquette strength but also causes the briquettes too thick, with more edges and more cinders and even not pressed into briquettes. Therefore, we should pay special attention to adjusting their spacing strictly when we assemble the up and down rollers. Generally speaking, the spacing should be controlled between two and three meters. We firmly believe that the most professional technical and quality of Zhongzhou Machinery will make you more satisfied!

The Zhongzhou briquetting machine enterprise is totally owing to its efforts on the research and development of briquette machines. We have been looking for the most reasonable solution to the permanently high quality production of ore powder briquette machines. The high quality ore powder briquette machines not only depend on good materials but need more technical support. Zhongzhou has pressed the various pulverized coal, breeze, lime powder, fluorite powder and other powdery materials that used in the production of ore powder briquette machines into finished briquettes to the fullest. Therefore, if you want to improve the production of ore powder briquette machines better, then the Zhongzhou Machinery will be your first choice.

Position:

Position: