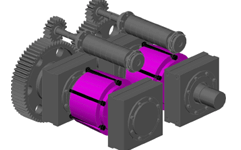

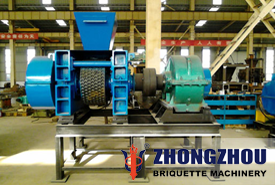

Iron oxide scale is a oxide corrosion product of steelmaking and rolling during oxidation at high temperature, composed of ferrous oxide, iron oxide, ferric oxide, the iron content is about 70%, there are two kinds method of utilize iron oxide scales for the Steel Corp : The one method is that materials applied directly to sintering, but the problem of this method is that the partial oxidation of iron will be a part of the dust fan sucked, will reduces the iron content of the yield, and the steel cost is high; the second is to add a certain proportion of iron oxide adhesive in briquetting process, bypassing the sintering and ironmaking, directly into steel smelting, it has the role of slag forming,attemperation, and reduction the cost of steelmaking. Zhongzhou iron oxide briquette machine is specially designed for iron powder, iron oxide, oxide coating, iron scale, iron ore concentrates,iron mud to make briquettes, high pressure, stable operation, high productivity, high degree of automation, production efficiency, low failure rate, convenient maintenance, so Zhongzhou iron oxide scale briquette machine are welcomed by many domestic and foreign enterprises.

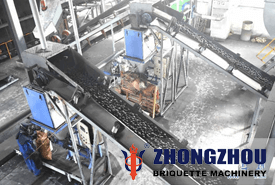

1 The iron oxide briquettes production line process(cold press)

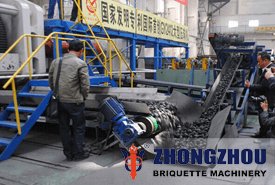

First of all, the collection of raw materials piled up in the specified site, after screening (large particle impurities, such as iron oxide, waste elimination) ,to press iron oxide without crushing, put a certian amount of coal, iron oxide and flux into a mixing equipmen together, here you can use a roller type mixer,then carry these materials into iron oxide briquette machine by belt conveyor, The out of the briquettes temperature is very high, generally around 30-40 degree celsius, The intensity of briquettes after natural air cooling is very good, user can pile up or loading fianl briquettes transport to steel mill.

2. The process characteristics of oxide iron briquettes production line

1) to add a binder for the ordinary cement, the cost is very low. The cement added briquettes are easy to be bursted when encounter high temperature in furnace, has advantages of fast slag forming.

2)The strength of cold briquettes with cement is very high, it is not easy to be broken in the transporting . To avoid loss in the fan sucked in the converter, improve the utilization rate of iron oxide scales, reduce the burden of dust collector.

3) Other accessories can be added into raw materials as needed, such as adding water quenched slag, dust, slag and other mineral powder.

4) The briquettes only be dired by nature air, the strength of oxide iron briquettes after 2-3 days of air drying can meet the using requirement, you can save a lot of energy costs.

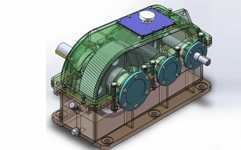

5) The whole set equipment is simple (high pressure briquette machine, vibration screen, silo, roller type mixers and conveyors etc.), the total investment of equipment is not more than 46,000US dallors, all equipment except high pressure briquette machine can be manufactured by customer self. these equipment occupied small area.

The requirements for raw materials of blast furnace sludge briquettes production:

1) The particle size of the raw material should be between 0-5mm.

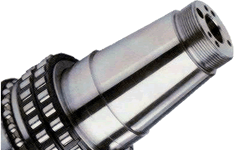

2) Can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

3) The feeding of whole produciton line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

Zhongzhou company based on metallurgical briquette pressure equipment technical services, to create maximum value for clients, The iron oxide briquette machine produced has the high pressure, high finished product rate, high strength, fully meet the requirements of the operation of converter steelmaking, cost reduction for the production practice of converter smelting, optimized operation,shorten the smelting practice, Speed up the rhythm of steel making, create the conditions for the realization of maximum benefit, we sincerely welcome all steel enterprises to explore, mutual benefit and win-win.

Position:

Position:

Description

Description

Parameter

Parameter

Advantages

Advantages

Cases

Cases

.jpg)

.jpg)

.jpg)

.jpg)