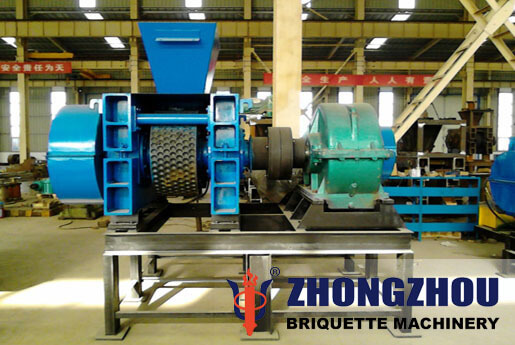

The word overloading is not strange for us, especially in the transportation industry, it is not allowed for overloading. No matter in passenger transport or freight transport, overloading is a hazard to both the vehicle itself and the road and it's not safe. Not just in transport, in the field of industrial production, there often appears the situation that machine works overload. Coal ash briquetting machine plays an important role in the production of briquette coal, thus in most cases, it operates overload. As for this case, I propose that we should ensure the workload stability of the coal ash briquetting machine as far as we can.

It is known to us that the size of the load and the stability has a great influence on the durability of coal ash briquetting machine. During the period of production and design, the coal ash briquetting machines all have their own standard carrying capacities, under which the operation will most meet the requirements of the coal ash briquetting machine. When beyond this carrying capacity, the wear degree of equipment parts and components will increase greatly. If this situation lasts too long, then the durability of the coal ash briquetting machine will be compromised enormously. As a result, there will appear a recurring malfunction and a regular replacement of the machine parts, then the productivity of enterprises is not increased but decreased.

The motor is the power source of coal ash briquetting machine, so the long-term overloading will do great damage to the motor. If the coal ash briquetting machine works within the carrying capacity, then the motor power will also operate within its rated power. However, once beyond this rated power, the loss will increased enormously. Then what should we do as for keeping the workload stability of coal ash briquetting machine?

Firstly, in order to keep the durability of coal ash briquetting machine, I think the machine should better not be worked under overloading. If there are requirements for long-term output and the company has enough idle money, then you can consider to add another device to reduce the burden. In the long run, it is a very powerful measure. Secondly, when there appears the situation that needs to increase the production capacity occasionally, to decrease the wear degree, the operation staff should start from the details when operating the equipment, for example, to increase the capacity of the coal ash briquetting machine in a regular and uniform way. During the operation, the staff should try to be smooth and avoid the sudden brake.

Position:

Position: